Application

► Touch control and optical coating industry

Applicable to display panel, touch panel and optical coating, touch panel, OGS key equipment and process industries such as glass substrates and soft substrates, coatings for mobile phones, tablets, laptops, large size TV Applications.

Anti-reflection (AR): 2AR, 4AR, 6AR

Refractive index matching + ITO (IMITO)

SiO2 and ITO films

Mo / Al / Mo film

ITO film

►Solar energy industry

The a-Si PVD achievement of amorphous silicon 3GW

CIGS: Mo, CuGa, Ni, AZO, Zinc Oxide

A-Si/ u AZO-silicon: aluminum, silver, nickel and chromium

HIT: ITO, silver, copper applications

Common specifications

Chamber material

-304 stainless steel

Main pump

-Dry pump or roots pump

-Turbo molecular pump

-Cryogenic pump

-Diffusion pumps, etc.

Extreme pressure

- No less than 8×10-7Torr/24h, Less than 8×10-7torr/24h@ Empty, Cleaning, Unloading

Leak rate(Helium leak detector)

- Less than 1×10-9Torr liters/sec

Winding speed

- 0.01~6.00m/min

Target - Metals: aluminum, chromium, nickel, molybdenum, gold, etc. - Oxides: ITO, silica, titanium dioxide, etc.

Thickness uniformity

- Less than 5% of the effective area

Adhesion

-100% (tape test)

-100% (tape test)

Control system

-Human computer interface control (PLC + PC)

-Selection function (manual / automatic / semi-automatic)

-Data feedback and real-time display function

| Max width diameter | 1350mm | 1700mm | 2100mm | 2500mm | 2900mm |

| Max roll diameter | 800mm | 800mm | 1000mm | 1000mm | 1000mm |

| Evaporation boat | 14 pcs | 18 pcs | 22 pcs | 26 pcs | 30 pcs |

| Evaporation pressure | 4x10-2pa(4×10-4mbar) | ||||

| Circulating water | 25m3/h | 30m3/h | 35m3/h | 40m3/h | 45m3/h |

| Average power consumption | 200KW | 230KW | 280KW | 300KW | 330KW |

| Rolling strip | PET:8-35; CPP:18-60; BOPP PVC:15-60;(µm) | ||||

| Max rolling speed | 720m/min | 1000m/min | |||

| Monthly capacity | 250T | 330T | 480T | 580T | 680T |

| Control way | Manual+Semi automatic+full automatic integrated/touch screen+PLC | ||||

| Remarks | Vacuum chamber can be made according to customer's special requirements. | ||||

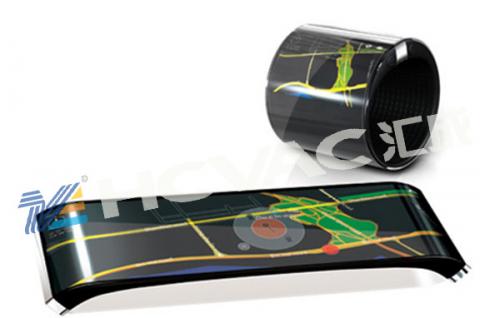

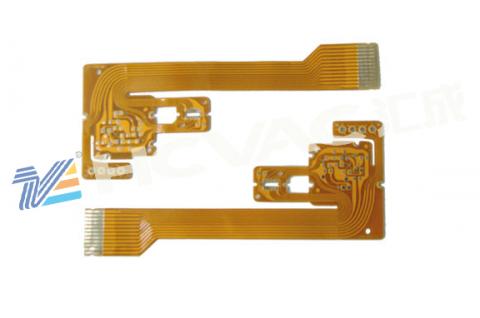

Roll coating and multi-layer coating can be applied to electronic paper , ITO film , flexible circuit boards, thin film solar , medical specimen , RFID antennas and water oxygen barrier film of the product . For electronic shielding film , car windows proof membrane , construction and decoration and other fields, such as metallic mesh electromagnetic shielding film , ITO transparent conductive film , anti-scratch ITO conductive film , electromagnetic shielding film, transparent film heating , energy-saving insulation film , PC copper-nickel film , PC heat shielding film , film capacitors , resistors with a dual -screen film products .