The device is merged into a vacuum for digital photoelectric window lens and shell material processing, which is aimed at current industrial solutions for the phone screen window cover, lens window lens, shell and metal parts of the vacuum coating performance:

Performance and yield

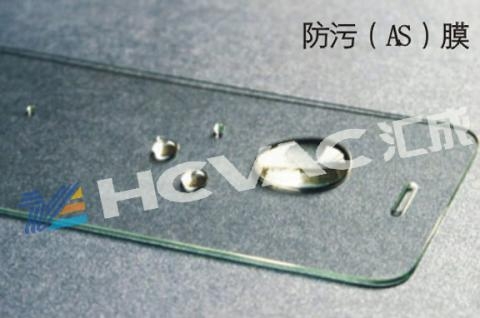

Improving AF (anti atherosclerosis in fingerprints or anti pollution performance) of vacuum coatings, and by increasing the yield and stability of equipment, then decreasing material consumption, to reach reducing its cost approaches.

Application

In addition to mobile phones, tablet computers, automotive displays, such as touch products. It can also be applied into other digital products, electrical appliances, bathroom accessories, plastic and metal parts of decorative and functional plated AF films, as coating, improving its smoothness, then easy to clean.

Decoration

It can be applicable for mobile phones, digital products, appliances, bathroom and other decorated products, through the bottom plating of color film and transparent dielectric multilayer film to achieve a variety of colors, tone and metallic luster, combining with silk screen, thermal transfer printing, laser engraving and drawing process, obtained with different colors, colorful luster, strengthen stripes and patterns of stereo vision.

Film series:Anti-fingerprint AF film

Color film + AF

Quality

Scratch test and water drop angle index:

1. Initial water drop angle 115-120 degree;

2. Abrasion test (#0000 steel wool, 1kg pressure, 10*10MM friction contact area, 40-60RPM friction cycle, 40-60MM friction travel, friction times 2000) and water contact angle 108-116;

3. The hardness of the surface to Asahi glass plate as an example, 9H Max. pencil hardness.

| Mode | HC-1618AF |

| Diamension | Ø1600x H1800mm |

| Vacuum chamber structure | Vertical double door |

| Vacuum system | Leybold/Edwards Machanical pump + Diffusion pump/Molecular pump + Polycold |

| Polycold system | Teperature -135℃,Pumping speed 90000L/S,Power supply 7.5KW |

| Ultimate vacuum | 5×10-4Pa |

| Pumping time | Atomosphere 5×10-3Pa less than 10 mins |

| Boost time | 1×10-3Pa to 1×10-1Pa less than 10 mins |

| Rotary fixture | Central bottom of the common rotation of the fixture shaft(Φ350mm * 9 axis) |

| Sputtering source | DC pulsed rotating cathode cylinder target sputtering source(20-100KHz Adujustable) |

| Ion source | Anode layer ion source or ion bar |

| Evaporation source | 20 boat impedance type evaporation source |

| Control | PLC + Touch screen main control system |

The series coating machine is suitable for the production of glass and plastic optical lenses, optical lenses AF and AS films, and also suitable for the preparation of color optical film of mobile phone window (glass or plastic) and plastic sheet.