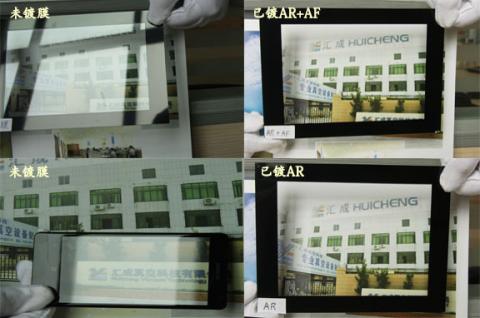

Electronic digital optical coating machine realize to achieve a good reproducibility and stable manufacture of high quality optical wavelength film, and including the decorative film comprises a functional film , nitride film at a low temperature.It can coat AR protective film on electronic products, and metal film for motor, enhanced reflection film, laser reflective mirrors, ITO film,band-pass filter, dichroic mirror, polarization sub-elements, applied in LED, optical oscilloscope, electronic components, digital products etc.

Features:

1、Can produce no wave drift high density optical thin film

2、Low temperature film, can cope with all kinds of use.

3、Only control the time, you can make complex optical film which can completely meet strict requirements of optical thin film design.

4、Utilize the mixed film made by high refractive rate material and low refractive rate material material.

5、Can produce nitride film, decorative film etc.

6、By increasing deposition efficiency, reduce size, reduce CO emissions and be of help environmental protection.

7、Compared with previous deposition apparatus, maintenance and cleaning durden reduce drastically.

8、Film area is about 1.0m2,can control the variation of the film thickness distribution within 0.5%

9、Utilize automatic sputtering control device, which makes sputtering technics realize automatic control.

| Dimensioin | Φ718x900mm | Φ950x1150mm | Φ1200x1350mm | Φ1400x1900mm | Φ1700x2450mm |

| Substrate umbrella stand | Rotary vertical umbrella stand | ||||

| RAS structure | sputtering source+oxidation source | ||||

| Exhaust time(deposition chamber) | reach 1×10-3Pa no more than 30min | ||||

| Exhaust time (front chamber) | from atmosphere to 7Pa no more than 7 min | ||||

| substrate heating temp | no heating | ||||

| Film thickness distribution | CV(variation coefficient)=no more than 0.5% | ||||

| Required electricity | 3 phase 200V±10% about 68kW(max electricity) | ||||

| Required cooling water | about 140L/min、18〜24℃(standard 20℃) | ||||

| Required compressed air | No less than 0.5MPaG(max0.7MPaG) | ||||

Coat AR protective film on electronic products, and metal film for motor, enhanced reflection film, laser reflective mirrors, ITO film,band-pass filter, dichroic mirror, polarization sub-elements, applied in LED, optical oscilloscope, electronic components, digital products etc.