The device using pulsed laser deposition (PLD) thin film deposition techniques, by means of pulsed laser rapid evaporation of the target, the generation and target composition film of the same. Through the continuous melting of mixed target, the production of multilayer film with different materials, through the control of the number of pulses, you can precisely adjust the film thickness to a single atomic layer. PLD method can gain possession of the steady state of the composition and structure of synthetic material criterions of thermodynamic theory, the manufacture of ceramic oxide and nitride films, metal multilayers and a variety of super lattice(superlattices).

Thin film growth principle:

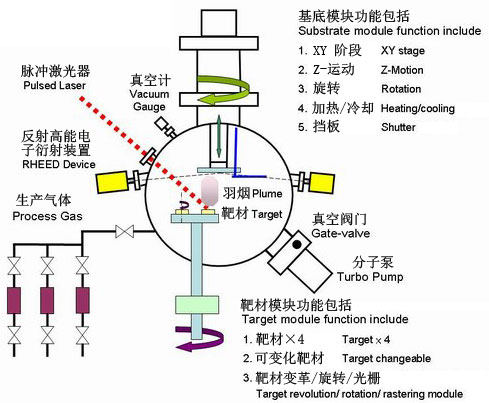

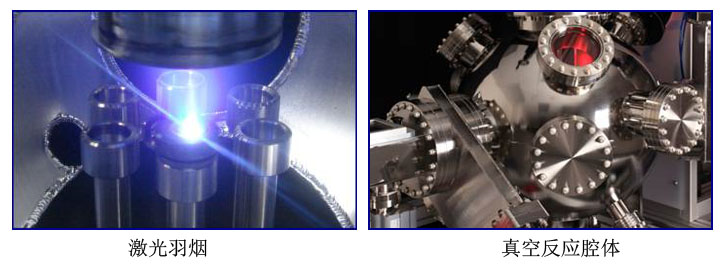

PLD is a laser pulse through the synthetic quartz window into the vacuum chamber radiation, then into the target membrane, the target, after irradiating, absorbed high density energy and formation of plume like plasma state, are then formed films on its opposite substrate.

Features:

| Mode | HCPLD-80 | HCPLD-120 | HCPLD-180 | HCPLD-240 |

| Vacuum chamber dimension | 8 inches | 12 inches | 18 inches | 24 inches |

| Vacuum system | Molecular pump + Dry mechanical pump | |||

| Pressure(Torr) | <10-8 | <10-8 | <10-8 | <10-8 |

| Max temperature | 950℃ | 950℃ | 850℃ | 850℃ |

| Ultimate pressure | 5.0×10-5 Pa | 5.0×10-5 Pa | 5.0×10-5 Pa | 5.0×10-5 Pa |

| Rotating frame | Male rotation | Male rotation | Male rotation | Male rotation |

| Rotation speed | 0~60 r/min | 0~60 r/min | 0~60 r/min | 0~60 r/min |

Applicable materials: high temperature superconducting, memory materials, oxide semiconductor materials, iron magnetic materials, three five materials<br>

Mainly used for the preparation of oxide film, superconducting thin film, semiconductor film, ferroelectric film, super hard film, etc., can be plated single film or multi-layer film.