The car industry has been to the high benefit and low cost mode, many auto parts will be electroplated chromium layer, and the vacuum coating product metallization mode of production is carried out in a no pollution of the environment, does not produce volatile organic compounds, through the preparation of a thin layer of metal to metal products components of expensive, this is the manufacturer can greatly reduce the cost of production solutions. Vacuum coating to make the car manufacturers to produce cost-effective auto parts, and formed as a leading supplier of vacuum coating equipment, as the global auto industry service, our system in line with international standards, we have a high-power cathode patent, preparation of coating more luster, than our system of any competitors soon, experience development of high efficiency, high production capacity of the equipment based on our years.

| Automotive Applications | Process description |

|---|---|

| Front lamp, tail lamp | Using the merged into preparing the reflective coating surface of the second vacuum coating mechanism of vacuum patent research |

| Exterior decoration, interior decoration |

The surface of UV coating, decorative aluminum coating, can be prepared in a variety of colors |

|

Hub |

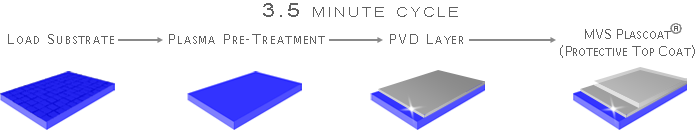

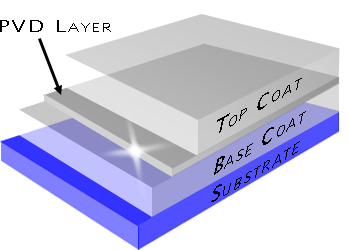

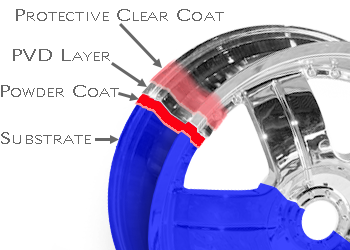

The wheels with metal layer and the powder coating based on PVD metal coating |

Reflection coating of car headlights and taillights plating on plastic mold injection molding, is the reflection of 90% Al (aluminum) and reflectivity of 95% ~ 98% Ag (silver) to achieve, merged into a reflective coating vacuum equipment plated over all headlights specifications, significantly more than the standard 10 minutes the NaOH test car industry, our system is designed to have a working cycle very fast, with injection molding machine production line operation. The following is a high-speed, four steps of high-quality automotive lighting coating process:

Vacuum coating after the coating can replace electroplating process effectively, so that the surface of metal car parts, Huicheng vacuum equipment can solve the vehicle industry is easy to wear, the plating coating specific good luster, even stronger, reflect the high repeatability. Huicheng vacuum provides all kinds of solutions, such as vacuum evaporation, sputtering, cathodic arc and composite coating mode.

|

Vacuum chamber dimensions |

430×1000mm | 540×1000mm | 700×1200mm | 540×1500mm | |

|

The type of power |

DC power supply, AC power, RF power, pulse DC power supply |

||||

|

Vacuum chamber structure |

Vertical double door, vertical, horizontal, single door single door pumping system | ||||

|

The vacuum system |

KT800/ molecular pump mechanical pump +630 mechanical pump +1200 +4400 roots pump x2 | ||||

| Vacuum range | 5×10-6 ~1.5 x10-4 mbar | ||||

| Pumping time |

The no-load air pumped to 5 × 10-2Pa less than 6 minutes |

||||

| Control mode | Manual and semi-automatic and fully automatic integration / touch screen PLC | ||||

| Remarks |

The vacuum chamber size can be customized according to customer products and special process requirements |

||||

To obtain the very good application in the automobile headlight, taillight, doorknobs, rearview mirror, piston, piston ring, alloy wheels, engine parts, synchronizer components, pumps etc…