PACVD Coating Technology

PACVD coating is the abbreviation of Plasma Assisted Chemical Vapour Deposition.

What is PACVD Coating Technology?

PACVD coating is the abbreviation of Plasma Assisted Chemical Vapour Deposition.

PECVD Coating Technology

The term PECVD coating is also used; E for Enhanced. Whereas in a PVD coating process the materials are evaporated from a solid form, in PACVD the coating results from a gas phase. In order to build carbon (diamond) coatings, acetylene (C2H2) or for silicium-containing coatings HMDSO (hexa-methyl-disiloxan) can be added. These gasses can be cracked in the plasma to become available for the coating.

DLC coating

An example of a PACVD coating is DLC coating (Diamond Like Carbon). It is used as a tribological coating, e.g. as an engine-coating for automotive components to make the component wear resistant and achieve friction reduction. Or it can be used as a tool coating, due to its anti-sticking properties very suitable for the machining of cast and wrought aluminium and plastic injection moulds.

Process description

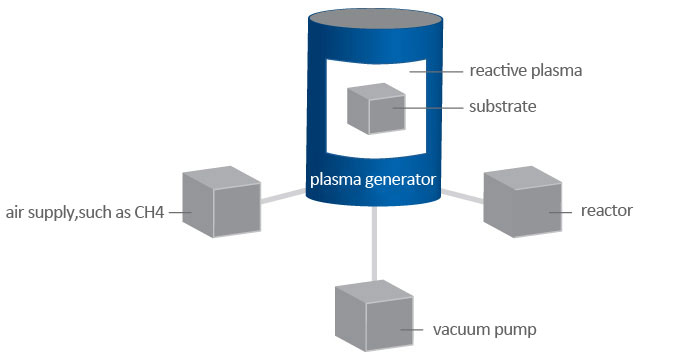

Plasma-Assisted Chemical Vapor Deposition (PACVD) activates chemical reactions through plasma excitation and ionization. Using this process, we can achieve deposition at temperatures as low as about 200 °C using pulsed-glow or high‑frequency discharges. Operating at these low temperatures allow the deposition of Diamond-Like Carbon (DLC) layers. DLC layers generated using PACVD are characterized by a low coefficient of friction and a scalable surface hardness.

PACVD and PVD combination

The PACVD process is frequently combined with a Physical Vapor Deposition (PVD) process to facilitate doping of DLC layers and the generation of complex layer architectures.

The principle of PACVD machine technology for the deposition of amorphous carbon layers.

Process basics(PACVD)

|

Coating thickness |

1 – 8µm |

|

Hardness |

1,000 – 3,500HV |

|

Temperature resistance |

350 – 400 °C |

|

Deposition temperature |

180 – 350 °C |

Advantages

High wear resistance

Low coefficient of friction

Corrosion resistance

Even two coated surfaces operating against each provide optimal performance and reliability

Typical applications

Tribological applications

Plastic injection and molding

Optical ndustry