PVD Coating Technology

What is PVD Coating Technology?

PVD is the abbreviation of Physical Vapour Deposition. PVD coating is a plasma coating deposition technology.

Vacuum Coating

The materials are vaporized under vacuum coating conditions to obtain a PVD coating. A vacuum chamber is necessary to avoid reaction of the vaporized material with air.

Features

PVD coating is used to provide new, additional features to the product: PVD coatings can have a vivid colour, there are wear resistant PVD coatings or reduced friction PVD coatings. PVD coating technology is a thin film coating in an environmentally friendly process.

Process basics

Coating thickness 0.5 – 10 µm

Hardness 1,000 – 4,000 HV

Temperature resistance 300 – 1,150 °C

Deposition temperature 200 – 600 °C

Coating structures

- Multilayer

- Nanocomposite layer

- Monolayer

- Gradient layer

- Micro alloyed layer

Advantages

-

Excellent coating adhesion even with low coating temperatures;

-

High production output, suitable for serial production;

-

Flexibility for different component shapes, sizes, and quantities;

-

Strong wear protection with low friction values;

-

Superior hardness, oxidation resistance, and reduced chemical reaction.

Typical applications

- Cutting tools

- Primary shaping, forming, and forging tools

- Plastic processing tools

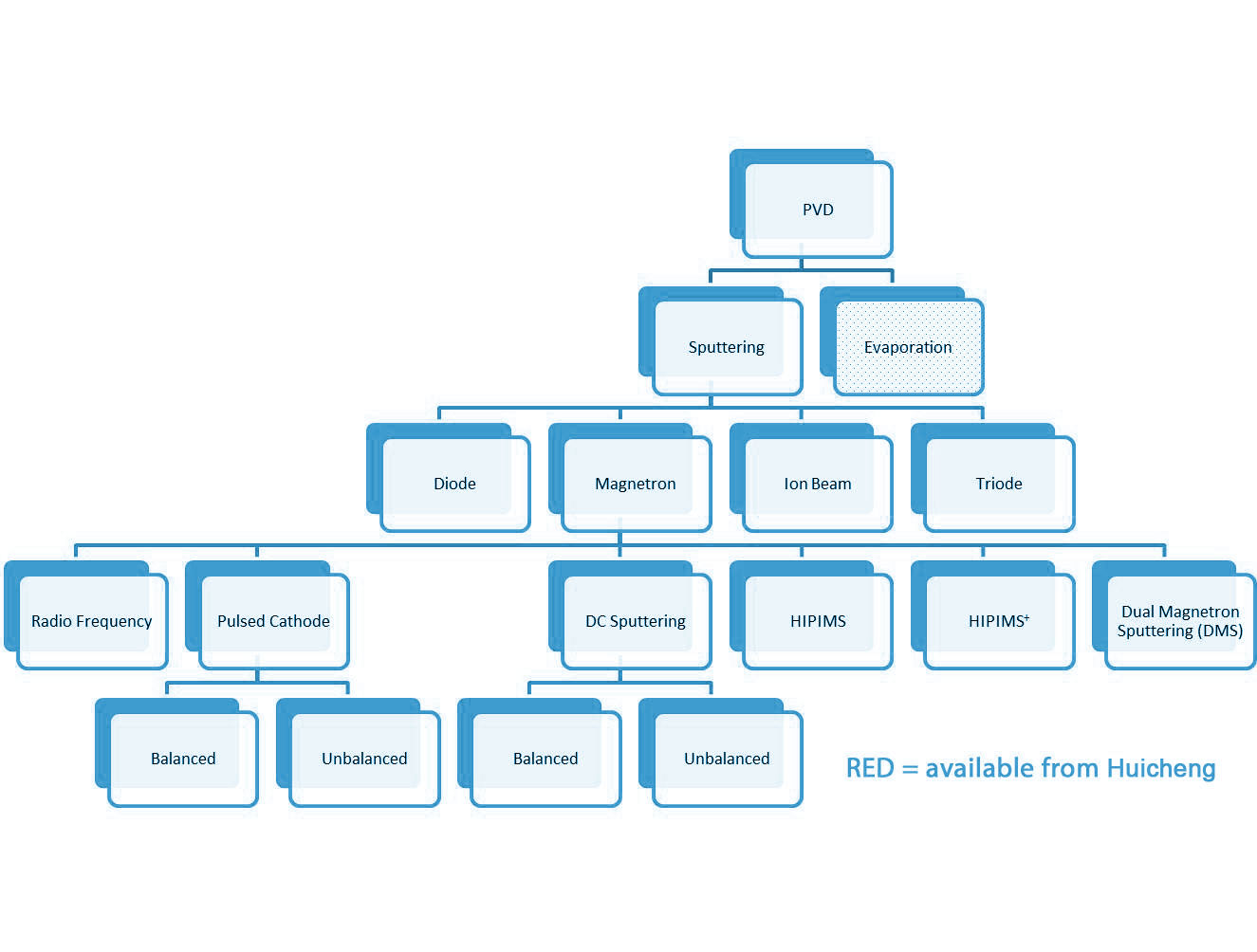

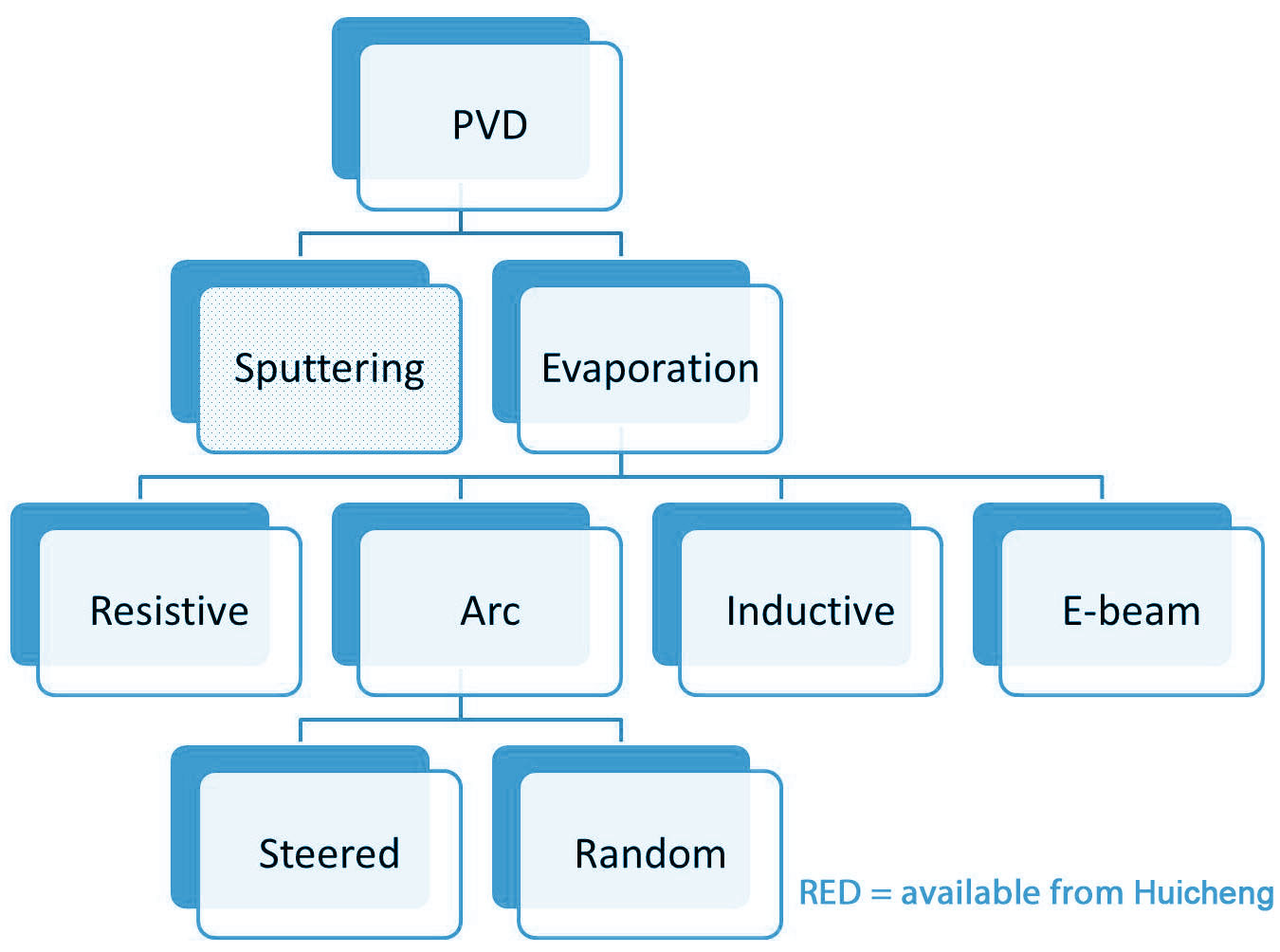

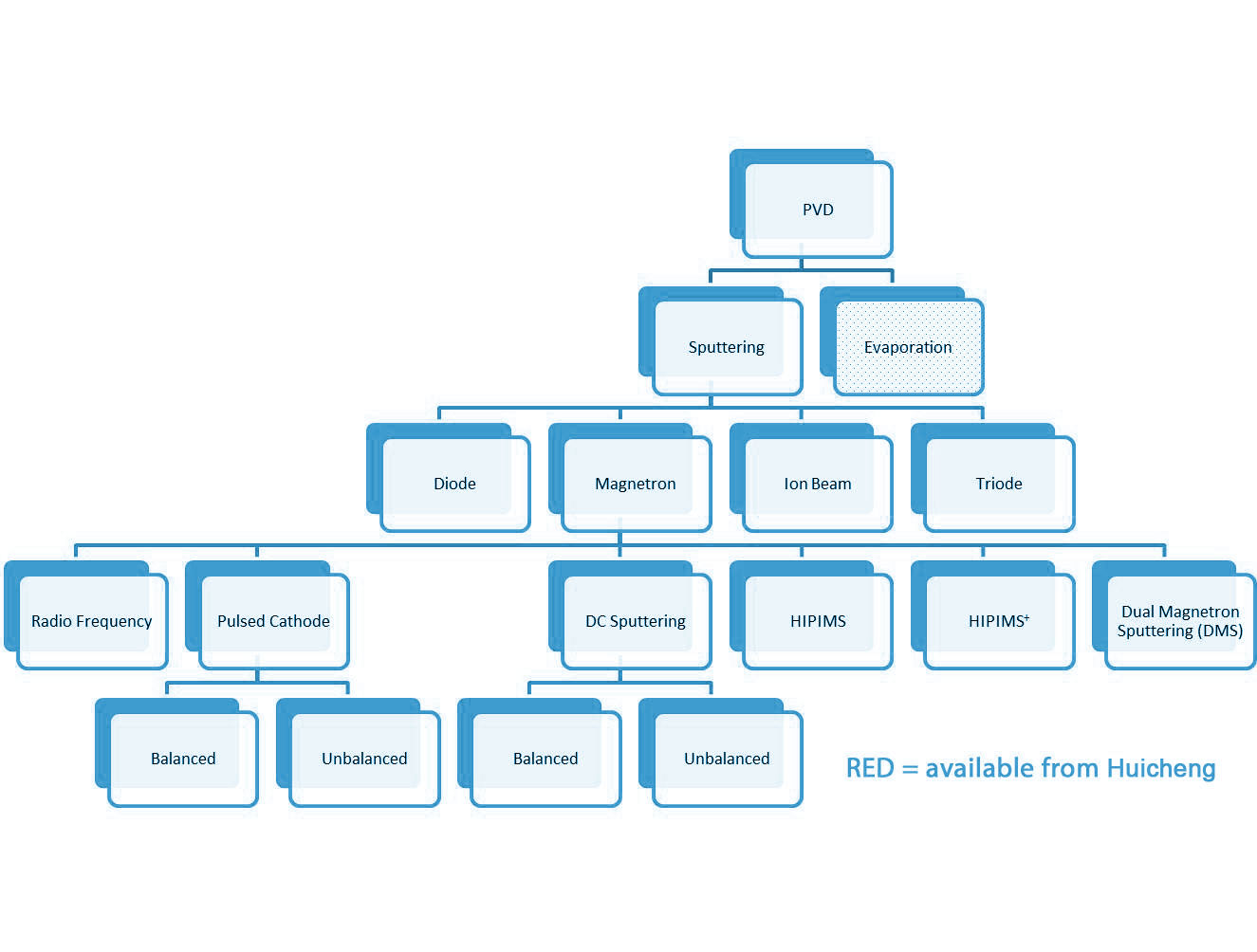

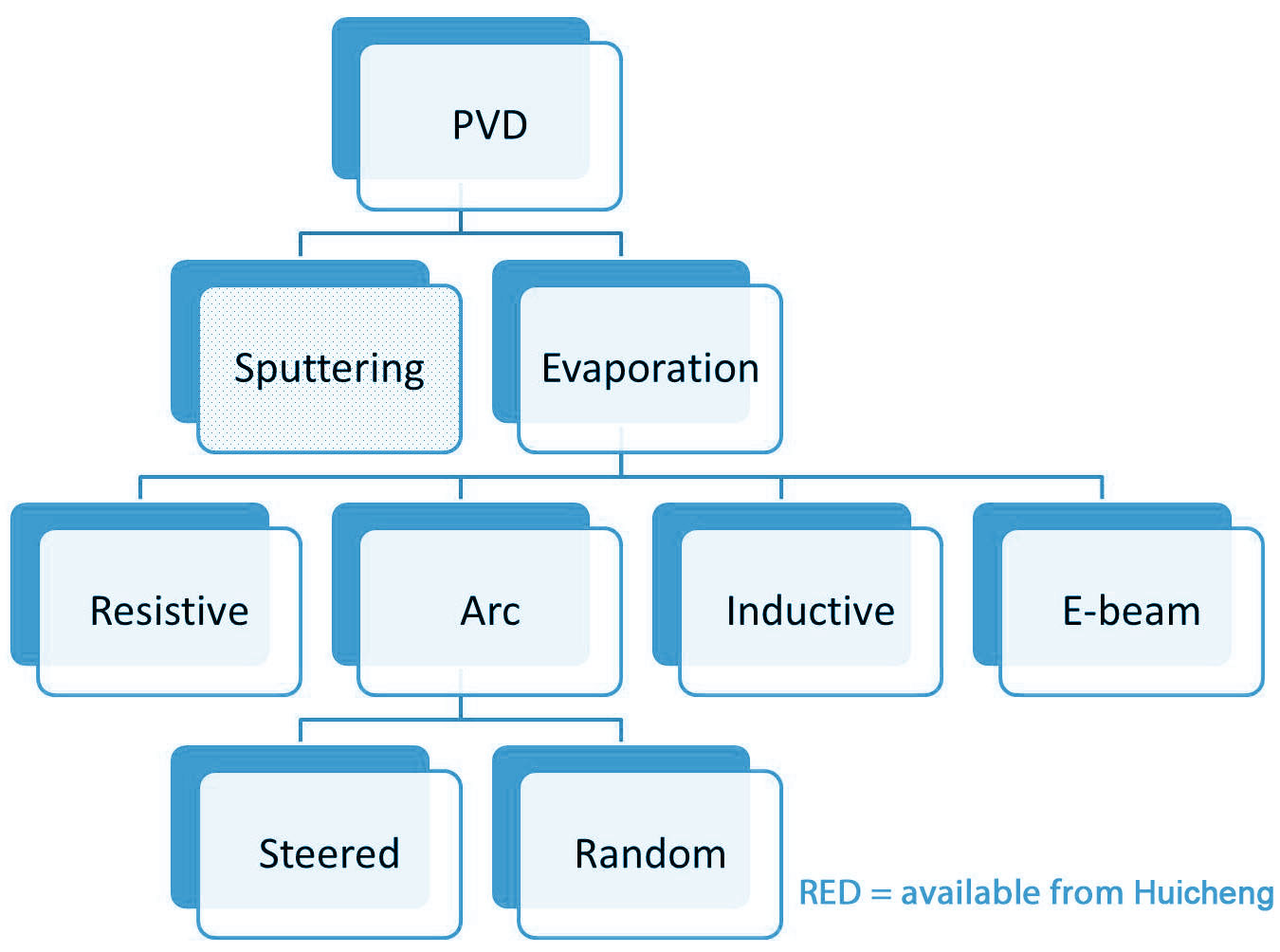

The PVD coating technologies in the red squares in the image below can be supplied in a HCVAC PVD coating machine.